new

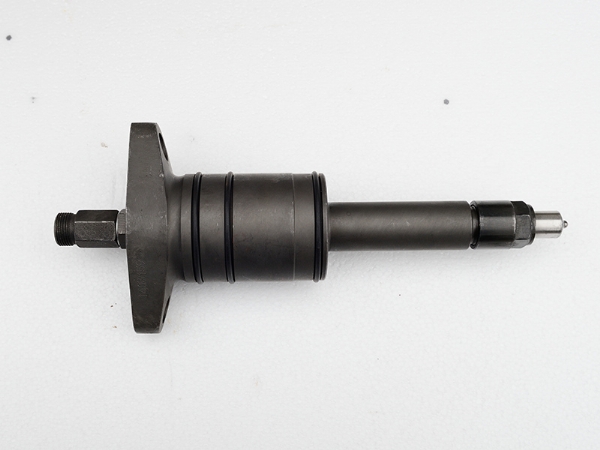

Maintenance of fuel injector

Maintenance of fuel injector

The fuel injector should be checked and adjusted once after working for about 700h. If the opening pressure is more than 1MPa lower than the specified value or the carbon deposit on the head of the needle valve is serious, remove the needle valve and put it into clean diesel oil, scrape the carbon deposit with wood chips, dredge the spray hole with fine steel wire, and conduct commissioning after installation. It is required that the fuel injection pressure difference of each cylinder of the same machine must be less than 1MPa.

In order to make the diesel injected into the cylinder by the injector burn completely in time, the oil supply time of the oil pump must be checked regularly. If the fuel supply time is too early, the vehicle will have difficulties in starting and cylinder knocking; If the oil supply time is too late, the exhaust will emit black smoke, the machine temperature is too high and the fuel consumption will rise.

The matching accuracy of the needle valve coupling of the fuel injector is high, and the orifice diameter is very small. Therefore, the clean diesel of the specified brand must be selected in strict accordance with the seasonal changes, otherwise the fuel injector will not work normally.

Do not collide with other hard objects or drop them to the ground when cleaning the needle valve coupling of fuel injector, so as to avoid bruise and scratch. When replacing the needle valve coupling parts of the fuel injector, the new coupling parts shall be soaked in hot diesel oil at 80 ℃ for about 10 s, and then the antirust oil shall be fully dissolved, and then the needle valve shall be pumped back and forth in the valve body in clean diesel oil for cleaning, so as to avoid the failure of sticking the needle valve due to the dissolution of antirust oil during the operation of the fuel injector.

Home

Home

Products

Products

Phone

Phone